Plastic Button Manufacturers in China

Wirwear offers a complete choice of the plastic button in various shapes and patterns. It gives clothes a fresh look. Further, our plastic buttons can be customized as per specifications.

- Stunning designs

- Strong tensile capacity

- Simple to fasten

- Trendy style

Wirwear Plastic Button

The plastic button is a small fastener, also referred to as a molded plastic button. It is frequently used in apparel trims. Frequently employ clothing products like shirts, pants, and more. Different materials, including ABS and acrylic, can be used to make plastic buttons.

Wirwear manufacture and supplies a comprehensive range of plastic buttons. We made buttons using quality plastic material. Also, we offer buttons in different designs and colors. For special requirements, our team can custom-manufacture plastic buttons. Please feel free to send us your design.

The plastic galaxy buttons are distinctive. It is immune to fading, cracking, and scratches. It can be washed and dry cleaned. Comes in multiple styles.

Made from 100% recycled plastic. Washable and dry cleanable. The buttons come in plastic-free packaging.

Available in a range of colors, designs, and sizes. Excellent for handbags, shirts, pants, etc. Glossy, smooth, and have no rough edges. Crack-resistant.

Each button has four holes. Available shapes include circles, ovals, squares, triangles, stars, etc. Suitable for adult and juvenile crafts.

The round plastic horn button has a superb finish. It has the excellent quality, stylish appearance, and multiple diameter options.

Our plastic snap buttons are functional and aesthetically pleasing fasteners. Frequently used in home textiles, garments, and bags.

Plastic Buttons Material Selection

Wirwear uses different raw materials to make plastic buttons. We’ve listed the following options below.

- ABS

- Acrylic (PMMA)

- Resin (Polyester)

- Nylon

- Urea, etc.

Features of Winwear Plastic Buttons

- Available in a variety of patterns

- Wide color choice: multi-color, pink, red, blue, etc.

- Size and dimensions: 8mm, 10mm, 9mm, and so on.

- Comes in 2-holes, and 4-holes, among others.

- Heat and Corrosion Resistance

- Wear-Resistance

- Lightweight

Plastic Buttons Applications

- Clothing

- Coats

- Shirts

- Blouses

- Uniforms

- Trousers

- Bags

- Suits; or even

- DIY Crafts.

Wirwear: Your Plastic Button Manufacturers in China

Wirwear has a solid reputation in clothing buttons and garment accessories. We manufacture and export plastic buttons to different international markets.

All products satisfy the highest quality requirements for material. It is following international environmental protection standards.

The size, color, and design options for plastic buttons are endless. Our buttons are always fashionable and on-trend. Call or email us, and we’ll show you our design buttons.

Additionally, we can make laser-painted buttons with logos.

Plastic Buttons Manufacturing Process

There is a no.1 tip in choosing the best material to make plastic buttons. You must consider how sturdy the final product must be. For example unsaturated polyester resin. It is resistant to problems like heat, weathering, and corrosion. That makes it perfect for large-scale manufacturing.

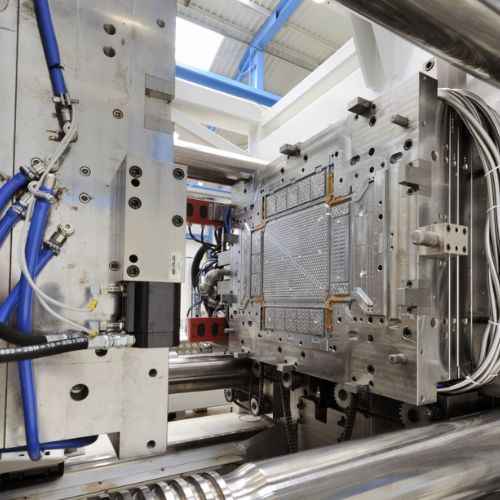

Once the material has been decided, Winwear will design new buttons. Molds or cutting devices are employed to achieve a uniform appearance. These tools can also be used to quickly create massive volumes of plastic buttons.

There are several ways the buttons can be made, depending on the material that was selected.

A plastic injection machine will melt the material and force it into the mold when utilizing a solid material, such as ABS. The buttons are taken out and split off from their runner after the plastic has cooled once more.

After they have been etched and finished, the final buttons are created by electroplating.

The button is placed on the hook and plated with an acid copper solution. It is to achieve the desired plating effect, and then the button is separated from the hook.

To make buttons shine, they are polished. In tumbling drums with water, abrasive material, and a foaming agent, buttons are maintained. For nearly 24 hours, the drums spin.

As they bounce about in the drum, the buttons become shiny and smooth. Finally, a hydro machine is used to wash and dry the buttons.

Before the finished plastic buttons are prepared for shipping, these buttons are lastly inspected for flaws. Each button is inspected for flaws by a quality control inspector, and any that are found are removed.

The flawlessly constructed and completed buttons are then put into packaging for sale. Then, it is sent to a warehouse for delivery to the customer.